- Worldepot Technology Co.,Ltd Copyright 2008-2012

- Tel:+86 755 28326071 Fax: +86 755 28326072 E-mail: info@worldepot.net

- Worldepot Technology Co.,Ltd,Silicone gifts/IMD/Cheap silicone gifts on sale/Water Transfer Printing/TPU/PC/Silicone Phone Case factory

Contact

Worldepot Technology Co., Ltd.

Tel : +86 755 28326071

Fax : +86 755 28326072

Skype: worldepot

Email: sales@worldepot.net

Site: http://www.worldepot.net

Scam Wechat & Chat Directly

Support

IMD Technology introduction

IMD Technology introduction

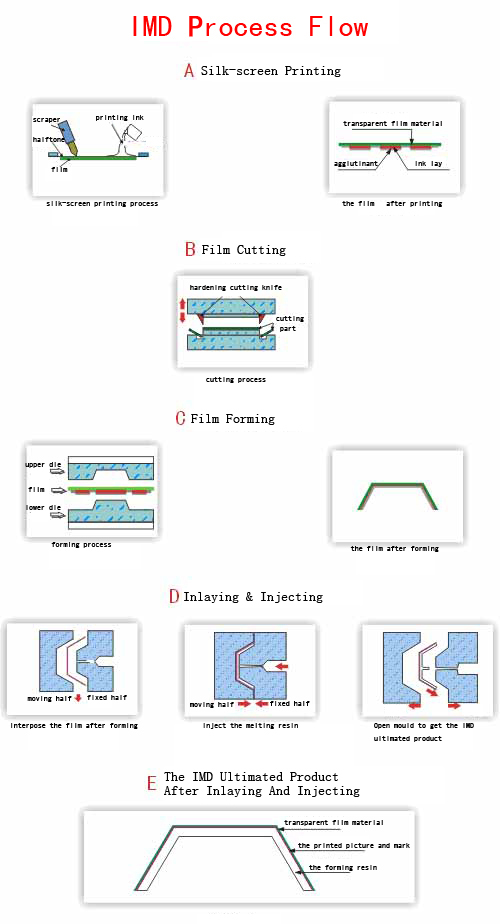

IMD stands for In Mold Decoration. IMD Technology ——Put the pre-treated film with decorative illustrations, logos and color inlay on the injection mold cavity for spotting and Injecting. Casting resin in the back of the film combines with the ink layer. Illustrations, logos and color of products place between the film and resin, so they will not be worn and corrosion-resistant chemical. It depends on the injecting mold ,and its shape, size can be maintained stably, so that it is more easily assembled. So IMD technology is also named spraying-avoided technology and it can be used in the panels of the automobile, communications, electronics, electrical appliances, instruments, apparatus, combining with decoration and function.

1. A Brief Introduction to IMD Technology

IMD Technology can be classified:IML、IMR、IMF technology.

IML stands for In Molding Label; it has been mainly used in packaging industry such as blowing plastic containers, shampoo bottles, bath bottles, cosmetic bottles, etc. I t has also been mainly used in edible box containers such as ice-cream cups, plastic cups, etc. Besides, It has application in beer boxes, beach table &chairs, sports articles (eg. Frisbees), etc. The technique is to put the labels printed and cut with PP&PET films inlay in mold cavity for Injection molding, so it call IML. Because the graphic ink of the technology is exposed and the surface of decorative part is flat, the film doesn’t need to mold.

IMR stands for In Molding Roller

The technique process: Print the release agent on the scroll-type PET film → print the graphic ink-lay →print adhesives → compound die to inject → separate the die sinking films from printing ink. In addition, the technique can be completed by film conveying → waste film receiving → CCD positioning operation.

Advantage: The whole roll of film could be series manufactured, not only patterns and characters are clear, but also the color is extremely bright, especially the effect of imitation plating is beyond compare.

Disadvantage: It can not be decorated with 3D three-dimensional shape, and there is no protective film on the surface that the illustrations are easily drop off. The cost is too high because the films are purchased abroad. In addition, the new product development cycle is extremely long, and the cost is greatly high, the color of the patterns can not achieve a low-volume flexible Change as well.

IMR mainly has application in lenses, signs and decorating parts such as cell phones, MP3, electronic products, etc.

IMF stands for IN Molding Film

The technique process: Print the pattern on the film → film forming → film slitting → in mold tectorial membrane to inject.

Advantage: It can be decorated with 3D three-dimensional shape, and the inks never wear, the membranes can print itself as well. Besides, patterns and textures can be freely designed .All in all, It has low-cost production.

IMF has been mainly used in communication mobile phone lenses, auto decorative parts, home appliances panels, etc.

2. IMD/IML product characteristics

※ Exquisite decoration illustrations, Containing logos and color, will not disappear ever through friction or chemical corrosion.

※ Illustrations, logos and color design can be changed at any time, without replacing mold.

※ Illustrations, logos of three-dimensional shape of products are very accurate, and it can resolve the status of the graphic dislocation.

※ Providing illustrations, and the window effect of logos back translucent and high translucent.

※ Convex bubble of Function keypad is uniform, and feel comfortable, and the life is up to more than 1 million

※ Three-dimensional changes in the product can increase the designers’ design freedom about the product design.

※ Composite molding process to achieve a seamless effect.

※ Optimizing process defects of the bad injection.

3. IMD/IML Applications

Household appliances industry: IMD control panels such as electric cooker, washing machines, microwave ovens, air conditioners, refrigerators;

The electronics industry: decorative surface shells, color shell sand signs such as MP3, MP4, calculators, VCD, DVD, personal digital assistants, the game boy, digital cameras , etc;

Automotive industry: dashboard, air-conditioning panels, interiors, automobile light shell, signs, etc;

Computer industry: keyboards, Buttons, mouse shells, surface shells, etc;

The communications industry: the phone keypad , phone lenses, color shell of mobile phones, the PHS and fixed telephone panels, window lenses , etc;

Other industry: medical equipment, cosmetics boxes, decorative boxes, toys, sports and recreation supplies, etc.

4. The Development Potential Of IMD

At present, IMD is a brand-new technology of plastic decoration which has been widely used in such industries as telecommunications, home appliances, electronics, automobiles, instrumentations, equipment, medical devices, toys, cosmetics. It can be a three-dimensional change, increase designer’s degree of freedom, and can be designed a variety of personalized products, so it advances with the times.

IMD technology not only can achieve injection molding, decorative integration and complete the process at once, but also can make a variety of special effects such as convex bubble buttons, metal mirror, or eliminate smooth, metal wire drawing pattern, the back light transmittance, Braille, Braille patterns, etc. It is highly decorative and functional.

IMD technology is the best new technology that substitutes for the plastic spray paint and electroplating processing. It also can reduce the Follow-up injection processing. To promote and popularize it in the plastics industry not only can really achieve energy saving and environmental protection significance but also generates huge economic benefits and environmental benefits for society and enterprises.